- Optimizing Operations

- blog

Calculating the ROI of logistics robots

Analysts claim that we’ve reached a tipping point when it comes to mobile robots entering widespread use in warehouse and manufacturing logistics. A recent report (Tractica) forecasts that global sales for logistics robots will rise from 194,000 units in 2018 to nearly a million (938,000 units) in 2022 – a Compound Annual Growth Rate (“CAGR”) of almost 50%! If that’s true, sales of logistics robots will match current global forklift sales (around 1.3 million units).

Companies investing in logistics robots are set to reap the benefits of increased efficiency, and profit, as well as ameliorate the problem of a largely absent workforce. Nevertheless, sound analytics should inform investment decisions. Projected Return on Investment (“ROI”) based on cash-flow is one of the most basic methods used to guide the decision-making process for any investment project.

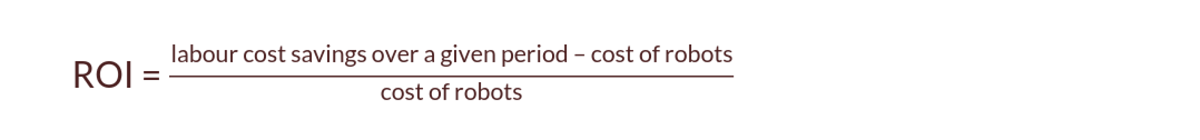

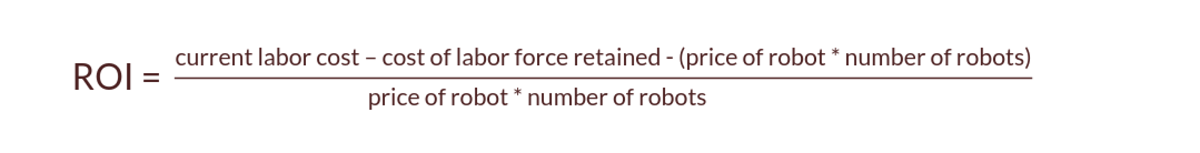

At its simplest, calculating robot ROI takes the cost of the robot against the wages of workers who would have needed to be hired to perform that job:

or

However, there are other costs (and savings) to consider that give much sounder insight into the returns achievable by investing in an autonomous mobile robotics system.

The following are some possible costs, savings, and alternatives that could factor into your decision.

Costs

(€) Initial purchase price (when buying a solution)

For a rough and ready ROI calculation, use the list price. However, getting a tailor-made offer that is in-line with what you specifically need is worth the time invested.

One-off expenditure

or in case of leasing,

Monthly cost over x number of months

(€) Delivery costs

The cost of delivery might have a significant impact, especially if your supplier is on a different continent. Not only in terms of delivery, having a supplier – and support – located in the same or a nearby time-zone will prove useful over the life cycle of your investment.

One-off cost

(€) Installation costs

Some suppliers charge installation as a separate cost. Choosing a flexible solution, one that doesn’t require special upgrades to your facilities and is easy to use will make a big difference here. A flexible solution might also mean one that offers more flexibility in the future when it comes time to scale the fleet and/or expand the scope of use cases.

One-off cost

(€) Extended Warranty (when buying a solution)

When comparing ROI across robotic systems, vet the length of the warranty offered in cases where you intend to buy. Suppliers that provide an extended warranty – while a one-off expense – can influence expenditures down the line. The alternative is to employ robots on a subscription basis thus eliminating this expense altogether.

One-off cost

(time) User training

Suppliers might charge for training employees as a separate line-item. Along these lines, find out if future training can be done internally or if you will need to seek out your supplier for additional sessions. Choosing a system that is very simple to operate with an intuitive interface may have a measurable financial effect.

One-off cost

or in case of external service,

Monthly cost = 1/12 of the annual estimate

(€) Operating energy

Ask your supplier to estimate the maximum energy consumption for robot charging, based on a similar use case scenario.

Monthly cost = 1/12 of the annual estimate

(€) Ongoing consumables, service and maintenance (when buying a solution)

Ongoing consumables, service, and maintenance include any spare parts that need regular changing, as well as any maintenance supplies and similar. If you intend to buy your robots, have your potential supplier explain their terms-of-service and scheduled maintenance to plan any costs that will arise past warranty.

Monthly cost = 1/12 of the annual estimate

(€) Decommissioning/disposal (when buying a solution)

Some parts of your robot may require special disposal and possibly will incur costs to dispose of (this may vary according to jurisdiction).

One-off cost (at the end of the expected product life-cycle)

(time) Inputting orders/tasks

This item refers to an estimate of how much of your employees’ time will be spent on inputting orders/tasks. A flexible platform, allowing both central management of tasks, as well as ad hoc ‘field’ inputs, can prove to be an excellent choice to keep this to a minimum.

Monthly cost = total monthly salary including 1/12 of annual benefits * number of operators

(time) Usage/effectiveness

Calculate an approximation of total productivity loss due to downtime (for extended charging of the robots, for example). Find the average revenue per employee work hour (annual revenue/total annual work hours of all employees in your company) to estimate the loss.

- Downtime due to initial installation and worker training

To arrive at a hyper-precise calculation of break-even, you might include the total downtime from the moment the robot is delivered to the moment it enters normal operation. In that case, choosing a solution that is simple to operate (with an intuitive interface) as well as flexible in terms of use case possibilities will prove invaluable.

One-off loss = Hours downtime * average revenue per employee work hour

- Downtime due to charging

For some robotic solutions, the charging times represent a significant drain on the total operational time, which becomes especially relevant in round-the-clock operations. In such contexts, there is clear value in having a solution that circumvents this problem – such as hot-swappable batteries, which would bring downtime to a point approaching zero.

Monthly loss = Hours downtime monthly * average revenue per employee work hour

- Downtime due to service and maintenance (when buying a solution)

Support is required with any equipment or IT platform. Ask your supplier for an annual estimate.

Monthly loss = 1/12 of the annual estimate of downtime in hours * average revenue per employee work hour

- Downtime due to adjustments

Your use case scenarios will (likely) evolve. New tasks will be added as you familiarize yourself with the robot’s capabilities. In cases of guided vehicles (AGVs), for example, different use cases will mean additional infrastructure requirements. In the case of LiDAR-only AMRs, their capacity to operate in some environments will be limited (such as those that lack static infrastructure like shelving). The best scenario is to choose a flexible solution that can do whatever you might need it to do.

Monthly loss = 1/12 of the annual estimate of downtime in hours * average revenue per employee work hour

Savings

(€) Reducing operator costs

Take into account how many labour hours would have been logged by workers doing the same task as your new robots. Ask your supplier for an estimate based on their data, but investing in a pilot project in your facilities would give you practical and actual insight.

Monthly savings = number of workers (possibly calculated on the number of working hours ‘exported’ to robots) * total monthly cost per worker including 1/12 of annual benefits

(time & €) Reducing employee turnover

Warehouse and manufacturing logistics are a segment especially vulnerable to a lack of workforce as well as relatively high turnover. However, filling a vacancy requires a considerable cost. One set of costs is related to the recruitment process, itself: posting the advertisements and conducting interviews. Another set of costs are related to the onboarding process: training, administration, medical check-ups, and similar. These should also take into account the cost of work hours spent by internal HR and training staff. The costs vary according to geography, but some conservative estimates put the total cost of hiring a new worker up 25% of the annual salary for the post. For this item, you will need your employee turnover rate and your internal estimate of the cost of hiring a new worker.

Monthly savings: 1/12 annual turnover rate * total number of employees * estimated cost of hiring a new worker

(€) Eliminating the costs of the equipment robots replace (e.g., forklifts)

Use real annual costs from your current operations for service and maintenance, ongoing consumables and energy/fuel usage. To reflect monthly cash flow, calculate the average monthly cost.

Monthly savings = 1/12 of the annual real maintenance and service cost

(€) Recouping the residual value of the equipment

Redundant equipment can be divested bringing one-off income.

One-off income

(€) Efficient use of space

Some automated robotic systems allow significant savings of space, primarily due to the slimmer profile and smaller turning radius of robots. The result is a more efficient use of space as shelving can be spaced closer together than would be allowable with forklifts, bringing either a direct saving in warehouse rental cost or removing the need to invest in new facilities. Ask your supplier’s input on possibilities in space savings based on their data and then use either real rental costs or an average commercial rate for your territory.

Monthly savings = estimate of space saving rate * total warehouse area * monthly rental costs per m2

(time & €) Usage/effectiveness of current equipment

The loss in efficiency – and concomitant loss of revenue – by continuing to use your existing equipment should also be taken into consideration to have a full picture. This loss relates not only to downtime due to maintenance but also to loss due to various staffing issues. The lack of workers is where the vulnerability of logistics and warehouse operations are impacted heavily – lack of workforce and high turnover rates. It has a significant effect.

You will need to calculate the average revenue per employee work-hour (annual revenue/total yearly work hours of all employees in your company). Please be aware that this is an approximation.

- Downtime due to maintenance and similar

Use a measured or estimated downtime for the current equipment in hours and calculate an average monthly cost.

Monthly loss saved = 1/12 of the annual estimate of downtime in hours * average revenue per employee work hour

- Downtime due to staffing issues

Downtime of your current equipment also includes idling when there is no one available to operate the equipment. Robots handling these tasks removes that lost revenue. Try to estimate an annual total downtime due to similar staffing issues.

Monthly loss saved = 1/12 of the annual estimate of downtime in hours * average revenue per employee work hour

What if you’re not ready to buy outright?

Engaging a robot fleet on a subscription basis (referred to as Robot as a Service, or RaaS) is an elegant way to avoid many of the most substantial costs, not to mention diminish risk. Gideon offers that option. Building a robot fleet on a subscription basis eliminates the following:

- A large initial purchase price,

- The necessity of an extended warranty to protect your investment,

- Ongoing consumables, service, and maintenance charges that can not only add-up and can be unpredictable month-to-month,

- Decommissioning/disposal.

RaaS allows you to adopt robot technology at a comfortable pace.